Tel:

15231678966 Website:

andymould.com

15231678966 Website:

andymould.com

Knowledge of punch mould

author:安迪模具 Release time:2016-01-10

At present, the precision of the production punch of domestic professional manufacturers can reach the level of plus or minus 0.002 mm, which is the leading international level. Professional machining of HL blade: the precision of punch, punching, punch and punching nut of the CNC iron tower is kept at plus or minus 0.002 mm. It adopts 980 numerical control punch and chong mother professional production workshop. High quality, quick efficiency, etc.

Stamping die in cold stamping process, the material is processed into parts. Stamping is at room temperature, installed on the pressure of mold to pressure on the material, make its produce a separation or plastic deformation, to obtain the required parts of a pressure processing method, are common in the industrial production. Stamping die is the process equipment of stamping production, it is a technology - intensive product. The quality, production efficiency and production cost of stamping parts are directly related to mold design and precision quality of mould parts.

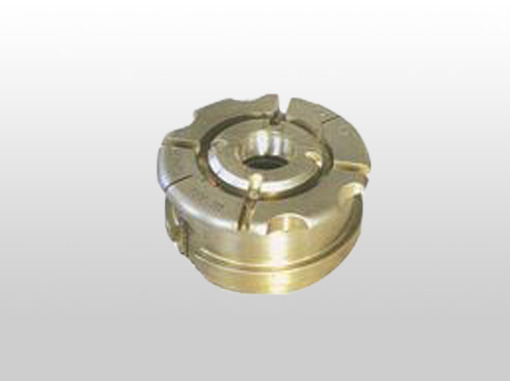

Hard alloy punch as part of stamping die, also known as hard alloy punch, belongs to replaceable mould consumables. Blunt needle according to the different material, shape, use can be divided into SKD, SKH, ASP, guiding, lash impact and blunt needle, smoking tooth blunt needle detector tip, hexagonal, molding blunt blunt needle, elliptical blunt needle, fan type punch, high speed steel, special-shaped needle and high quality requirement of carbide rods, guangdong side also habit called tungsten steel needle.

In industrial production, hard alloy punch for stamping die can be made according to different requirements of the product. Especially in the progressive die complete sets of production operation, such as computer chassis, above will have a lot of cooling hole, there are many mobile phones, electrical appliances, machinery is used above, the ordinary drilling machine, or cars, milling machine, can only work out round hole, and punching, large punch, processing hundreds of holes at the same time.