Tel:

15231678966 Website:

andymould.com

15231678966 Website:

andymould.com

Mould material and heat treatment

author:安迪模具 Release time:2016-01-10

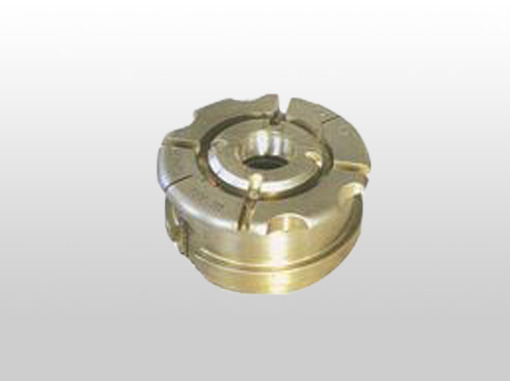

The correct selection of mold material is the basis of improving the service life of the stamping die. According to the different requirements of the production parts, the corresponding materials should be selected. Commonly used mould materials include: casting material: mocr cast iron, ball mill cast iron, ht300, etc. Forging materials: t10a, cr12mov, 7crsimnmov, etc. The commonly used convex concave modes include t10a, CRWMN, cr12mov, cr12, etc. When the mold designer chooses the material, the material's performance, function and economy should be considered.

According to the failure analysis of the die, 45% of the dies are due to improper heat treatment. The wear, adhesion and fatigue fracture of the die often occur on the surface, so the machining quality of the die surface is very important to improve the mould life. For different materials, reasonable heat treatment of different properties is a key factor to improve the life of die. Shall be made for the heat treatment process is rigorous, the mold designer must indicate the parts when making homemade parts heat treatment, heat treatment effect directly affects the eligibility of mold production parts, safety and service life of mould. In addition, the temperature should be controlled in the process of heat treatment. If the temperature is too high, the parts will harden and harden, resulting in brittle and brittle fracture. If the temperature is not enough, the quenching and hardenability cannot meet the technical requirements, will lead to the deformation of the parts. If the protection measures are not taken care of when hardening, the surface oxidation and decarbonization of the mould can be reduced, the wear resistance, fatigue strength and anti-occlusion capacity can be reduced, and the service life can be affected. Quench cooling speed or oil temperature too low, easy to produce quench crack.