Tel:

15231678966 Website:

andymould.com

15231678966 Website:

andymould.com

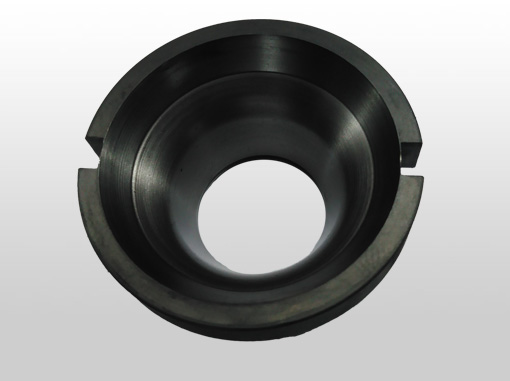

A mold is a type of replication tool

author:安迪模具 Release time:2015-12-17

All manufacturing is just for products. Similar equipment, machinery, mould, all related to the manufacturing industry chain, machine tools, die steel, hot runner, stamping mould, plastic mould, plastic machinery, plastic machinery automation for the final products and services.

In order to design the most original, exquisite, practical, reasonable product style, so have the industrial design, mould design and so on; In order to produce better quality and durable product quality, we have so many high precision machine tools, numerical control, machinery and other equipment. For faster, more efficient, mass-produced copies of products, there is a mold, a replication tool that serves directly to produce products. From a piece of iron to a pair of high precision molds, to mold with plastic injection molding, to copy a large number of high quality products, manufacturing stretches out filling, filling the protagonist is glittering and translucent get rid of the product, is the public can touch, and the best supporting role identity is an irreplaceable molds.

The mold does not have the luxuriant coat that the product has, the mould is just a piece of hard to use the driving to move the steel. Buy a need to pass design, drawing, material, rough machining, heat treatment, etc (like electric processing. Wire cutting, CNC machining, etc.) - finishing (fine mold, province mold, polishing, electroplating, etc.) - assembly - mold fitting test and process characteristics of steel.